- PSU steel major’s production capacity to reach 35 mnt by 2030-31

- Company has recorded around 20% reduction in emissions since 2005

- Technological collaborations, R&D driving decarbonisation initiatives

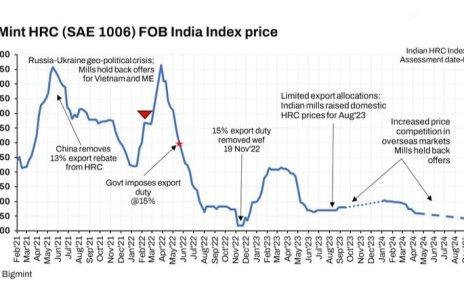

Morning Brief: As part of its pledge to achieve net-zero carbon emissions by 2070, India is committed to a set of Nationally Determined Contributions (NDCs). SAIL planning to cut CO2, Some of India’s most ambitious commitments in the short- to mid-term include 1 billion tonnes (bnt) of cumulative emissions reduction and achieving 50% of renewables capacity by 2030.

As the country’s premier PSU steel company, SAIL (Steel Authority of India Ltd.), is committed to driving sustained decarbonisation measures aligned with the government’s NDCs. SAIL has declared a capacity augmentation project. Steel production stood at around 19.2 million tonnes (mnt) in the financial year 2023-2024. However, capacity is expected to climb to 35 mnt by 2030-31.

As BF-BOF steelmaking comprises around 99% of the company’s total production, SAIL’s decarbonisation pathway reflects the toughest challenges that the Indian steel industry must encounter in its journey toward low-emissions production.

Technology adoption

The decarbonisation programme of SAIL has been segregated into three distinct phases based on the existing architecture and logistics, availability of technology, product basket and market dynamics, technology infusion rate and availability of fund, future expansion plan, breakthrough technological developments, government policies and, above all, the company’s social commitment, a SAIL-EMD official told BigMint.

Coke dry cooling plant (CDCP) facility in tall coke oven batteries, BF top gas pressure recovery turbine (TRT), coal dust injection (CDI) and waste heat recovery (WHR) in large volume BFs, torpedo ladle for hot metal transfer from BF to SMS, WHR system in sinter plants, etc. are some of the key technological interventions that were implemented by the company during Phase 1 (2005-2022-23).

As per sources, the company is striving to go beyond SAIL’s NDC target of 2.3 tCO2/tcs by 2030 (Phase 2).

The key levers for achieving CO2 intensity of less than 2.3 tCO2/tcs by 2030 are:

Enhancing energy efficiency: Optimising coke rate, enhancing CDI rate, enhanced by-product recovery and gainful utilisation, online metering and automation for all forms of energy, etc.

Resource optimisation: Increased raw material beneficiation capacity, implementation of pellet plants, increased prepared burden, enhanced use of pellets.

Increasing share of renewable/non-fossil energy: Installation of rooftop, land-based and floating solar power plants and hydel power.

Promotion of circular economy: Use of BOF slag as acidic soil ameliorant/fertiliser, micro-pelletisation facilities for gainful use of plant solid wastes.

Developing carbon capture utilisation and storage (CCUS) facilities

Shifting to alternate steelmaking route: Feasibility of introduction of DRI-EAF, with provision of H2 injection, currently being explored at SAIL’s Durgapur Steel Plant (DSP).

Decarbonisation initiatives

Collaborations for injection of COG & H2: SMS Group is exploring innovative and sustainable solutions at SAIL-BSP related to injection of coke oven gas in one of the BFs, better utilisation of excess COG in BFs and saving of BF coke. Also, injection of H2-based fuel in SAIL-BSL is being explored. Initially lower amounts of green H2 shall be injected in the BF through a few tuyeres, which will gradually be increased to approximately 10 kg/thm.

Primetals Technologies is facilitating SAIL-RSP in implementation of sequential injection of oxygen with high pressure in BF and other environmentally friendly technologies such as CCUS.

SAIL has collaborated with the National Centre of Excellence in Carbon Capture and Utilization (NCoE-CCU) of IIT, Bombay for developing technology for carbon capture (from IISCO steel plant), its utilisation and geological sequestration in nearby coal bed methane (CBM) wells.

Biochar has been injected in one of SAIL’s BFs on trial basis. The techno-commercial parameters are being evaluated for developing infrastructure for gradually increasing injection of biochar to partially substitute pulverised coal injection (PCI) coal.

Article Credit: Bigmint